Carton vertical sorting machine:

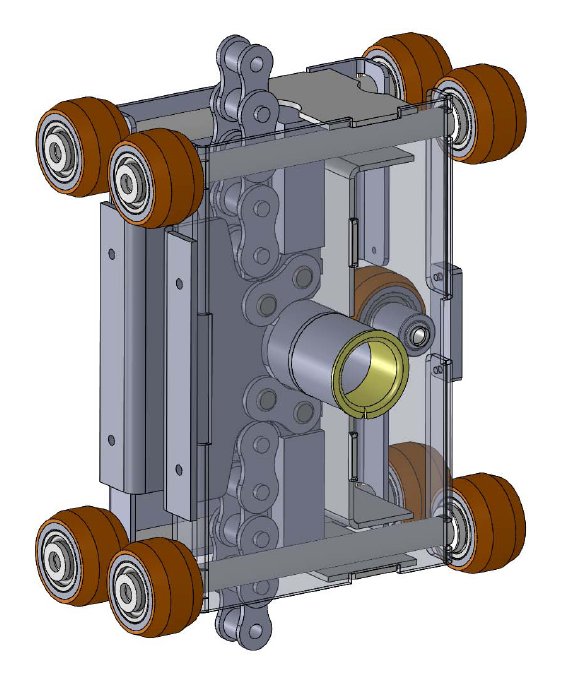

The main working principle of vertical sorting machine is that the chain consists of two large sprocket wheels rotating through the chain. The fork part on the chain is used to pick up the goods when passing through the roller table machine, and then put it into another roller table line to complete the sorting action of the goods by moving the receiving roller table.

Vertical sorting machine can satisfy the input and output of multiple ports, and also can satisfy the input and output of the same port.

One. main mechanical structure and features:

Body: hot rolled steel Q235/t5 is adopted for the frame, and polymer material is adopted for the chain bar.

Support: folding and welding type support, made of 5mm hot rolled steel plate bending and welding, connected with the frame bolt, and can be connected to the ground by adjusting the foot base, conveying surface height adjustment +25mm.

Drive device: motor drive

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m. Spraying color shall be specified by party a's color card.

Two. Main performance and parameters:

| Description Integral frame type, standard 300mm wide column, standard height L=2m, if L < 4m, integral frame; Standard modularization of each frame; Chain specification 16a-1; Sprocket wheel specification 16a-1-76z; The drive is placed on the top frame of the hoist; Use with roller table machine or chain machine; |

Type

| |

Name | Description |

Delivery length L (mm) | L=220~550 |

Conveying width W (mm) | W≤500 |

Transport height H (mm) | H≤L |

The mouth height D(mm) | D≥750(Or dig a hole) |

Movements itinerary E(m) | E≤12 |

Length of inlet and outlet conveyors F(mm) | F=640 |

The device width L1 (mm) | W1=1071 |

The device width L2 (mm) | W2=1360 |

Equipment is highly H (mm) | L=E+1200 |

Floor opening size (mm) | 1200*1270 |

Motor power P (kw) | E≤4m,P=0.37B; 4m<E≤6m,P=0.55B; 6m<E≤8m,P=0.75B; 8m<E≤10m,P=1.1B; 10m<E≤12m,P=1.5B; |

Conveyor speed V(m/min) | V≤30 |

Load per fork plate chain M(Kg) | M≤50 |

Fork plate length B(mm) | B=585 |

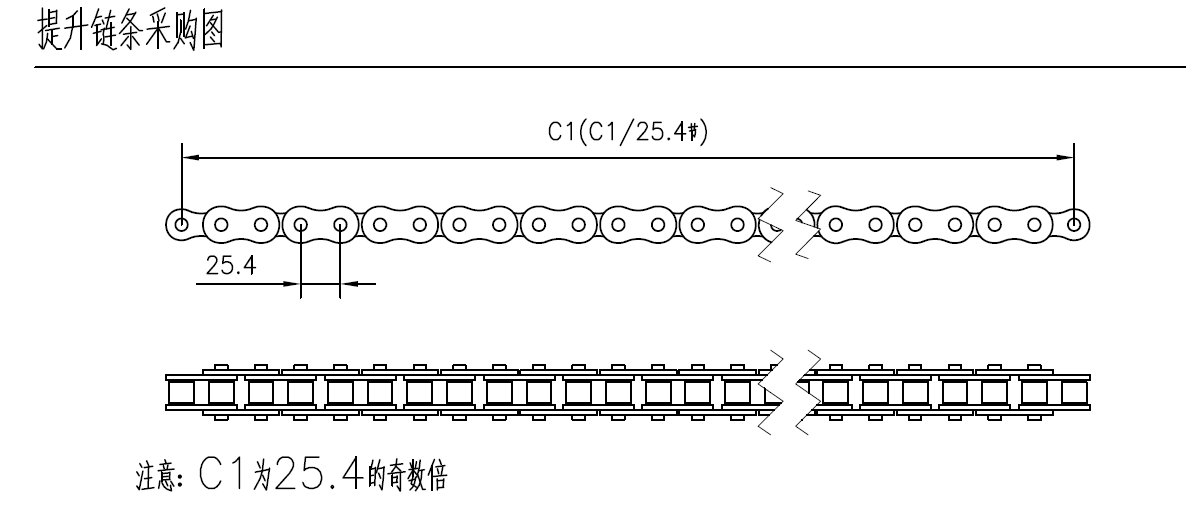

Fork plate spacing C (mm) | C is an odd multiple of 25.4 |

Fork plate A wide A(mm) | A=415 |

Delivery efficiency vertical η | Vertical 2000 PCS/hour |

The total load (Kg) | 300Kg/m |

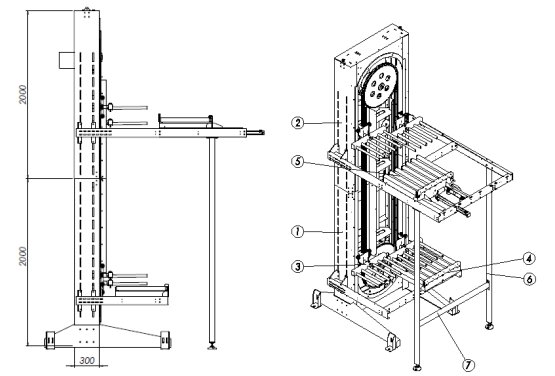

Structure diagram:

Order number | Name | Name |

1 | VC bottom rack components | The seal plate |

2 | VC top rack components | |

3 | VC fork assembly | |

4 | VC roller loading components | |

5 | VC A sorting table component | |

6 | VC roller support leg A | |

7 | VC roller support leg pull rod | |

8 | Lift chain 16a-1 | |

Note: the height of each floor of the standard rack is 2m. The length of the last middle segment is not a standard | ||

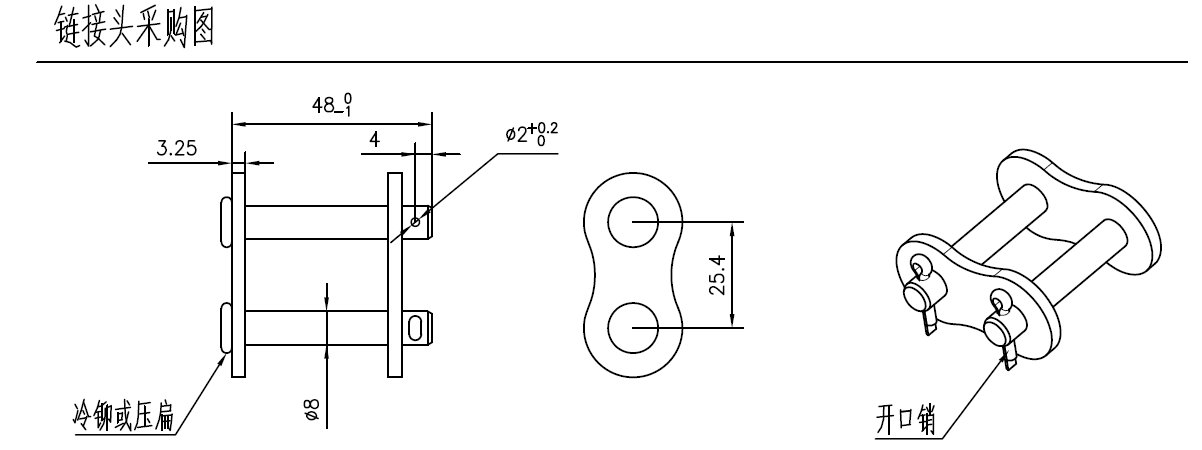

Chain assembly details:

Note: wear two 16a-1-5z chains (including two long link heads) in the body of the car.