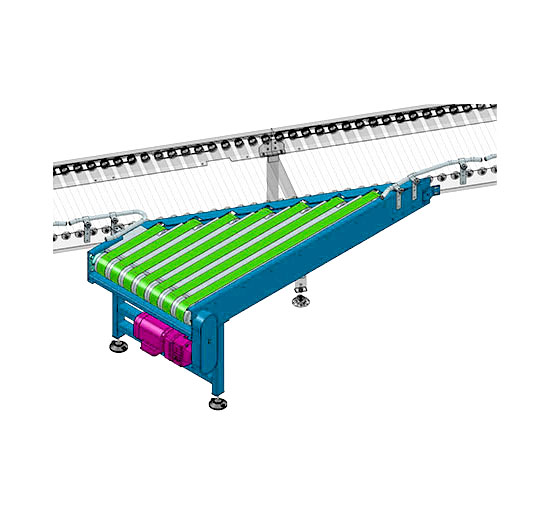

Carton narrow-belt merge&spurs:

Multi-column narrow-band confluence machine's main working principle of gear motor is driven on the shelf by the chain or synchronous drive roller rotation, driven roller to drive more narrow belt running, because of every narrow belt length is differ, form a certain Angle, generally is 30 °, for docking with the main line of the belt conveyor, the goods on the belt is running, thus promote the shunt or confluence conveying process.

One. main mechanical structure and features:

Belt: the belt is made of PVC belt with low friction guide strip of hot-melt interface, with low noise and avoid deviation. The narrow belt is separately tensioned, and the tensioning force can be obtained by adjusting screws on the tensioning device.

Body: hot rolled steel Q235/t4 is adopted for the frame, and ultra high molecular polyethylene (UHWMPE) is adopted for the belt tow.

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m. Spraying color shall be specified by party a's color card.

External parts configuration: the motor should be SEW, belt should be west green, bearing base should be TR, bearing should be ha shaft.

Two. Main performance and parameters:

| Description The frame is formed by cold bending of 4mm steel plate The belt is tightened separately to prevent deviation

| |

Type | ||

Standard | Standard | |

Angle(mm) | 30° | |

Height (mm) | H(min)≥300 | |

Inner width B (mm) | 400 ≤ B ≤ 800 | |

Motor power (Kw) | 0.75 | V ≤35 m/min |

1.1/1.5 | V >35 m/min | |

Conveyor speed V (m/min) | V=20-100 | |

Machine load (Kg) | Max ≤50 | |