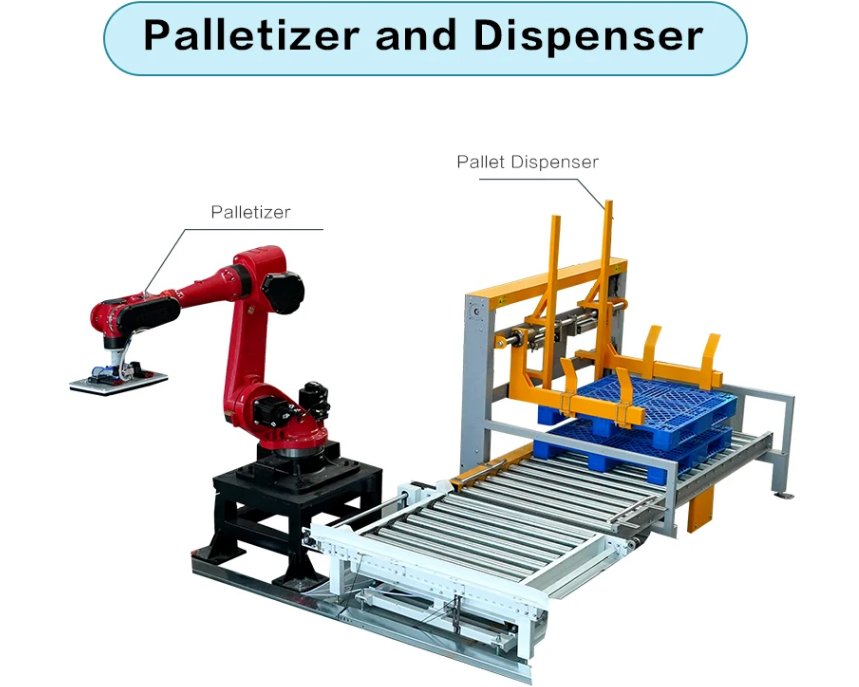

Carrying on the above, earlier we introduced the first two steps of the pallet dispensor operation process, the last step of today's introduction of the automatic start function.

Automatic start: In the equipment stop state will be [manual / automatic] switch to automatic, will be placed neatly in the appearance of the same specifications of the perfect stack placed on the conveyor, press the [start] button, three-color light, green light is always on, the device enters the automatic state. Stack machine on a set of counterpoise photoelectric detection of stack board into the fork cylinder to keep open state, lifting mechanism rises to the middle of the bit close to stop (such as no action, please check the fork cylinder extends the position of the magnetic switch whether there is a signal), the fork cylinder closed in place will be the lower number of the second piece of pallet hooked up, the fork cylinder shrinks the position of the magnetic switch indicator lights up, lifting mechanism rises to the top again close to the bottom piece of pallet with the upper layer of The conveyor roller line will start to transport the separated pallet board to the next station, the stack conveying line for the stack of photoelectric detection of pallet board, the lifting mechanism down to the lowest position close to the switch, the fork to open the lifting mechanism rises again to the middle position, and so on, repeat the cycle of depalletizing until the removal of a complete stack of pallet boards.

Careful users will find that, in fact, YUPACK shared this knowledge about the stacker is complementary, although we introduced today is the automatic startup function of the stacker, but it is in fact the perfect interpretation of the working principle of the stacker, if you are familiar with the operation process of the stacker, the principle of the stacker is also through, in fact, it is not very difficult, right?