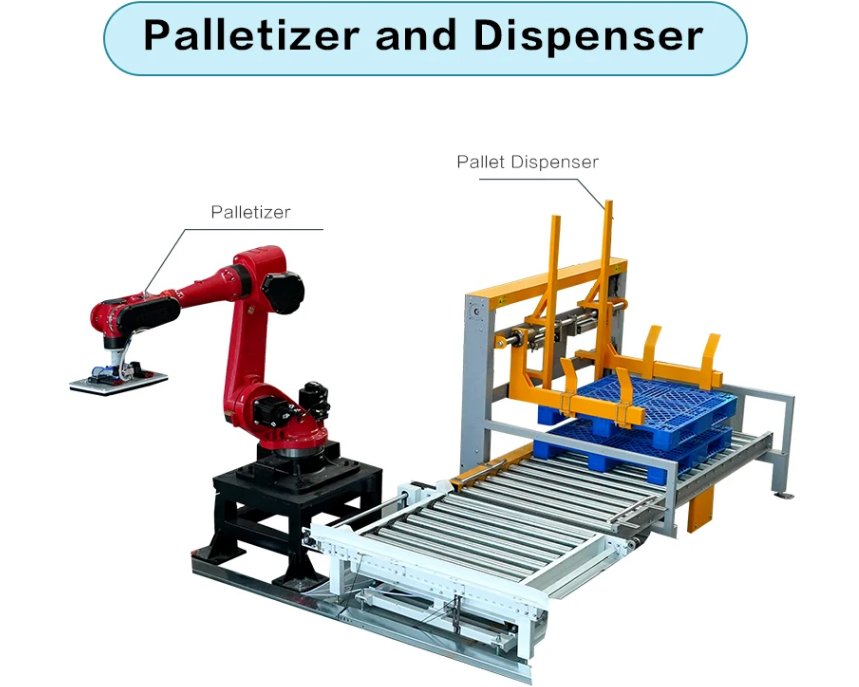

YUPACK has shared with you the working principle of the stacker, and today YUPACK is going to focus on sharing with you the operation process of the Pallet dispensor , the operation of the stacker is divided into three steps, manual operation, reset start and automatic start.

Today we will first share with you the first two operation processes, and in the future articles, YUPACK will continue to share the latter operation steps:

(1) manual operation: in the stopped state of the equipment will be [manual / automatic] selector switch to "manual", respectively, switch [up / down] control lifting mechanism lifting action; switch [fork extension / fork shrinkage] control of the fork cylinder opening and closing action, the button [for the stack line] button to start for the stack conveyor line, and then again press the [for the stack line] to stop the stack conveyor line. Press 【Stacking Line】 again to stop the stack conveying line.

(2) Reset start: switch the [manual/automatic] selector switch to "automatic" under the equipment stop state, press the [reset] button, reset case 1: there is no pallet on the stack line, the lifting mechanism will drop down to the lowermost proximity switch, and the fork cylinder will open; reset case 2: there is already a pallet on the stack line, and the lifting mechanism will stop at the uppermost proximity switch position, keeping the fork closed and the fork closed. The lifting mechanism will stop at the top position of the proximity switch, keep the fork closed, and the stacker will enter the ready state after the reset is completed. (Note: If the stopping position of the lifting mechanism before reset is not in the upper, middle and lower three close to the switch, please manually lower the lifting mechanism to the lower close to the switch).

You need to emphasize that these steps are not required every time you turn on the machine, generally only in the debugging stage of the new machine will be used, and then in the process of using, you only need to press the start button, the equipment can be automated, without the need to set up from scratch. However, if you want to change the pallet specification, you may need to carry out simple debugging, and may need to set up from the beginning, but if the manufacturer has already recorded all the pallet types into the PLC of the pallet feeder in advance, you can also choose them directly on the touch screen, and do not need to set up from the beginning.